Ho roala lipompo

1, oxidation ea mouoane: tlanya mouoane oa metsi a mocheso o phahameng, bokaholimo ba sebopeho sa filimi ea oxide, adsorption e pholileng e ntle, e ka bapala karolo ea ho fokotsa likhohlano, ha e ntse e thibela pompo le lisebelisoa tse sehang lipakeng tsa bond, tse loketseng. bakeng sa ho sebetsa tšepe e bonolo.

2, kalafo ea nitriding: pompo ea holim'a nitriding, ho etsa lera le thatafatsang holim'a metsi, le loketseng ho sebetsa tšepe e entsoeng ka tšepe, aluminium e entsoeng ka tšepe le lisebelisoa tse ling holim'a lisebelisoa.

3, mouoane + nitriding: melemo e felletseng ea tse peli tse kaholimo.

4, TiN: seaparo sa khauta se mosehla, boima bo botle ba ho roala le mafura, le ts'ebetso ea ho khomarela e ntle, e loketse ho sebetsana le lisebelisoa tse ngata.

5, TiCN: lesela le boputsoa bo botala, boima ba hoo e ka bang 3000HV, ho hanyetsa mocheso oa 400 ° C.

6, TiN + TiCN: seaparo se mosehla se lefifi, se nang le boima bo botle ba ho roala le lubricity, se loketseng ho sebetsana le lisebelisoa tse ngata.

7, TiAlN: ho roala bohlooho bo botala, boima ba 3300HV, ho hanyetsa mocheso ho fihlela ho 900 ° C, ho ka sebelisoa bakeng sa ho sebetsa ka lebelo le phahameng.

8, CrN: ho roala silevera e bohlooho, ts'ebetso ea lubrication e phahame, haholo-holo e sebelisetsoang ho sebetsana le litšepe tse se nang ferrous.

Ho roala ha pompo ho na le tšusumetso e kholo ts'ebetsong ea pompong, empa hajoale, baetsi le bahlahisi ba litlolo ba sebelisana 'moho ho ithuta ka mokhoa o khethehileng oa ho roala, joalo ka LMT IQ, Walther THL, joalo-joalo.

Lintlha tse amang ho tlanya

A. Thepa ea thepa

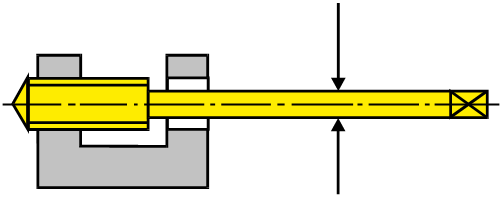

1. Sesebelisoa sa mochini: se ka aroloa ka mekhoa ea ts'ebetso e otlolohileng le e otlolohileng.Bakeng sa ho tlanya, e otlolohileng e betere ho feta ts'ebetso e otlolohileng, 'me ts'ebetso e otlolohileng e lokela ho nahana hore na ho pholile ho lekane.

2, ho tlanya shank: ho tlanya ho khothaletsoa ho sebelisa shank e khethehileng ea ho tlanya, ho tiea ha mochini, botsitso bo botle bo khethoa ho khetha shank ea tapping ea synchronous, ho fapana le hoo, ka hohle kamoo ho ka khonehang ho khetha shank e feto-fetohang ka puseletso ea axial / radial.Sebelisa square drive neng kapa neng ha ho khonahala, ntle le lipompo tse nyane tsa bophara (

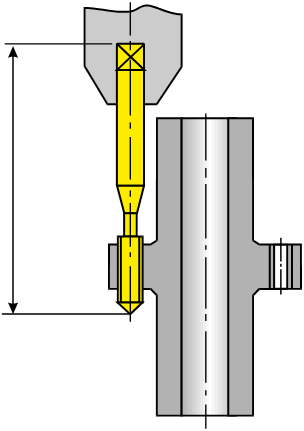

3. Maemo a ho pholisa: bakeng sa ho tlanya, haholo-holo lipompo tsa extrusion, tlhokahalo ea sepholisa ke lubrication > pholiso;Ha e le hantle, e ka lokisoa ho ea ka maemo a mochine oa mochine (ha o sebelisa emulsion, ho kgothaletswa hore mahloriso a be moholo ho feta 10%).

B. Sesebedisoa se tla sebetswa

1. Thepa le boima ba mosebetsi o sebetsitsoeng: ho thatafala ha lisebelisoa tsa mosebetsi ho lokela ho ba tse ts'oanang.Hangata ha ho khothalletsoe ho sebelisa lipompo ho sebetsana le workpiece ho feta HRC42.

2, ho tlanya sekoti se ka tlase: sebopeho sa sekoti se ka tlase, khetha karolo e nepahetseng;Ho nepahala ha dimensional tsa lesoba le tlase;Boima ba lerako la lesoba le tlase.

C. Mekhoa ea ho sebetsa

1, lebelo: lebelo le fanoa motheong oa mofuta oa pompo, thepa, thepa e sebelitsoeng le boima, melemo le likotsi tsa lisebelisoa tsa ho tlanya.

Hangata e khethoa ho latela litekanyo tse fanoeng ke moetsi oa pompo, lebelo le tlameha ho fokotsoa tlasa maemo a latelang:

▶ ho tiea ha lisebelisoa tsa mochini ho fosahetse;Ho otla ho hoholo ha pompo;Pholiso e sa lekaneng;

▶ Thepa ea ho theipi kapa ho thatafala ha ho tšoane, joalo ka manonyeletso a solder;

▶ pompo ea lelefatsoa, kapa ho sebelisoa molamu o ekelitsoeng;

▶ Mohatsela, serame se ka ntle;

▶ Ts'ebetso ea matsoho, joalo ka ho phunya libenche, ho phunya rocker, joalo-joalo;

2, fepa: ho tlanya ka thata, fepa =1 pitch/turn.

Ho tlanya ka mokhoa o bonolo, 'me phetoho ea matšeliso ea shank e lekane:

Fepa = (0.95-0.98) pitch/revolution.

Malebela a mang mabapi le khetho ea lipompo

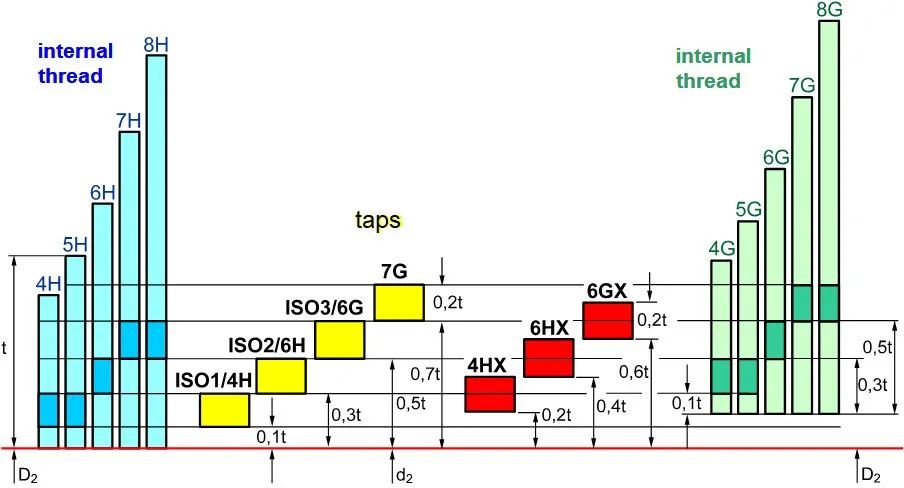

A. Mamello ea lipompo tsa limaraka tse fapaneng tsa ho nepahala

Motheo oa khetho: eseng feela ho latela boemo bo nepahetseng ba khoele e lokelang ho etsoa ho khetha le ho fumana boemo bo nepahetseng ba pompo.

▶ Thepa le ho thatafala ha sesebelisoa se sebetsitsoeng;

▶ Thepa ea ho tlanya (joalo ka maemo a mochini, molamu oa ho koala, selikalikoe sa ho pholile, joalo-joalo);

▶ Theipi ka boeona e nepahetse le phoso ea tlhahiso.

Mohlala: ho sebetsana le khoele ea 6H, ts'ebetsong ea tšepe, ho ka khetha pompo e nepahetseng ea 6H;Ts'ebetsong ea tšepe e bohlooho, hobane bophara bo bohareng ba pompo bo apara ka potlako, katoloso ea lesoba la screw e nyane, ka hona ho loketse ho khetha pompo e nepahetseng ea 6HX, bophelo bo tla ba betere.

Ela hloko ho nepahala ha lipompo tsa Sejapane:

▶ OSG ea ho itšeha e sebelisa sistimi e nepahetseng ea OH.Ho fapana le maemo a ISO, sistimi e nepahetseng ea OH e qobella bophara ba sehlopha sa mamello ho tloha moeling o tlase, 0.02mm e 'ngoe le e 'ngoe e le boemo bo nepahetseng, bo bitsoang OH1, OH2, OH3, joalo-joalo.

▶ OsG ea Extrusion Tap e sebelisa RH precision system, RH precision system e tla qobella bophara bohle ba mamello ho tloha moeling o tlaase ka ho fetisisa, e 'ngoe le e' ngoe ea 0.0127mm e le tekanyo e nepahetseng, e bitsoang RH1, RH2, RH3 joalo-joalo.

Ka hona, ha o nkela sebaka sa OH precision tap ka ISO precision tap, 6H ha ea lokela ho nkuoa e batla e lekana le boemo ba OH3 kapa OH4.E lokela ho khethoa ka ho sokoloha kapa ho ea ka boemo ba sebele ba moreki.

B. Karolo e ka ntle ea pompo

1. Hajoale, tse sebelisoang haholo ke DIN, ANSI, ISO, JIS, joalo-joalo.

2, ho latela litlhoko tse fapaneng tsa ts'ebetso ea moreki kapa maemo a teng ho khetha bolelele bo nepahetseng, bolelele ba lehare le ho sebetsana le boholo ba lisekoere.

3. Tšitiso nakong ea ts'ebetso;

Tlanya khetho ea lintlha tse tšeletseng tsa mantlha

1, mofuta oa khoele ea ho sebetsa, metric, Brithani, Amerika, joalo-joalo;

2. Mofuta oa lesoba le ka tlaase la khoele, ka lesoba kapa lesoba le foufetseng;

3, sebetsa workpiece lintho tse bonahalang le thatafala;

4, workpiece feletseng khoele botebo le botebo ba lesoba tlase;

5, workpiece khoele ho nepahala;

6, ponahalo ea maemo a pompo (litlhoko tse khethehileng li hloka ho tšoauoa).

Nako ea poso: Sep-22-2022